Introduction of use cases by LMUe6000-JM

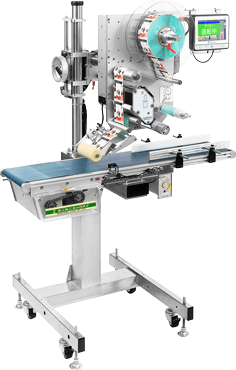

LMUe6000-JM

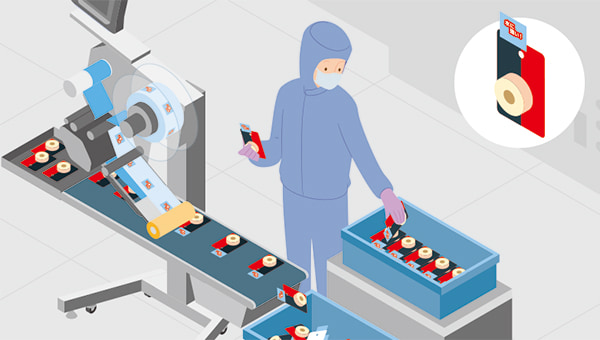

EDM's labeling machine that applies on the top "LMUe6000-JM" realizes easy automatic label applying on the top of the product offline. It is used not only on the top surface but also in various situations.

【Case01】

Customer wants an automatic labeling machine

that can be easily installed and removed.

01

Requests from customers

- Some products were produced only for a few months a year, and the product label was manually applied to the top lid of the container.

- Despite months of production, securing workers during that period was an annual challenge.

02

Proposal from EDM

We propose LMUe6000-JM, which is easy to install and remove and can be easily handled by anyone.

03

Evaluation from customers

Simply place the product on the conveyor and it will be automatically labeled in same position, improving productivity and quality. Since it comes with casters as standard, it was easy to move.

It is compact in size, can be installed in a small space, and can handle sudden production.

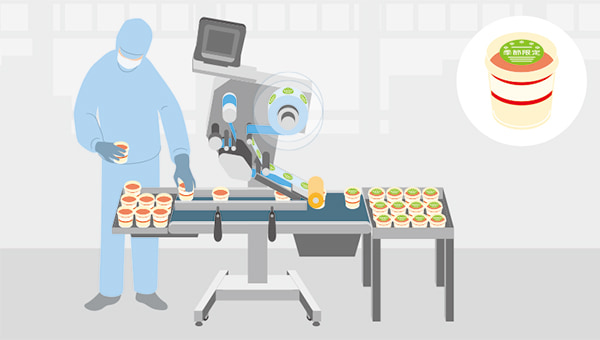

【Case02】

Customer would like to apply a lot of POP labels

on a cylindrical container.

01

Requests from customers

- Customer would like to apply a lot of POP labels on a cylindrical container.

- It was decided to apply the POP label to the cylindrical container, but it is difficult for even experienced workers to apply it by hand. Since there are many productions, I would like to apply inline instead of offline.

02

Proposal from EDM

Using the standard guide of "LMUe6000JM", we propose to transport the container with the container laid down so that the side to be applied is facing up, and apply the label.

03

Evaluation from customers

Thanks to the standard guide, it was able to apply the POP label in a stable position. It operates in-line at high speed, but the applying accuracy is stable. We are very satisfied with the low cost automation.

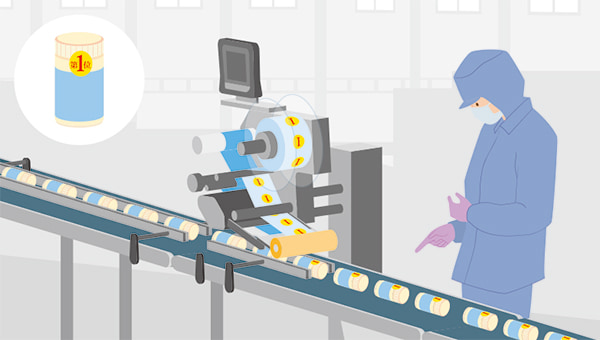

【Case03】

Customer would like to apply a one-point label to products

that are packaged in multiple packaging lines.

01

Requests from customers

- It is costly to install an automatic applying machine on all packaging lines.

- They also considered hand-applying, but whether we it secure human resources in the face of labor shortage.

02

Proposal from EDM

We propose to collect products together in the post-process of the packaging line and perform automatic applying with "LMUe6000-JM".

03

Evaluation from customers

It required minimum of capital investment, and the personnel who were supposed to be hand-pasting could be sent to other work. For automatic applying on the packaging line, labels are often replaced at high places, but with the "LMUe6000-JM", even women could easily replace the labels.

【Case04】

Customer wants to apply a lot of sealing labels

while they don't have enough manpower and time.

01

Requests from customers

- Since it is a product for major convenience store chains, it is produced in large numbers and it is difficult to manually apply it.

- If even the folding of labels is automated, it will take time and cost to install the equipment.

02

Proposal from EDM

We propose a method to complete the sealing label attachment by applying a label to the upper surface of the lid of the pack container with "LMUe6000JM" and folding the label when the worker packs it in a box.

03

Evaluation from customers

It can be introduced in a short period of time, equipment costs and a series of workers can be minimized, and delivery that meets the requirements of major convenience store chains has been achieved.

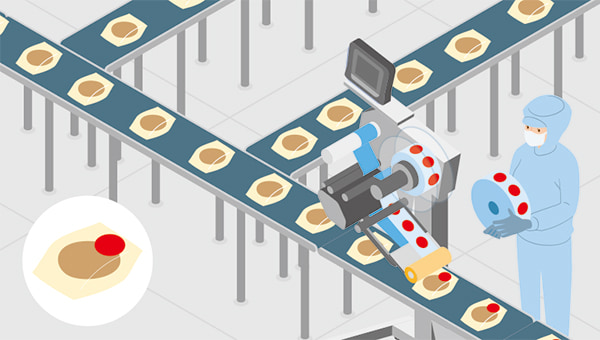

【Case05】

Customer wants to apply a POP label

on a transparent container in a hurry.

01

Requests from customers

- Normally, it is a product that is not labeled, but we decided to apply a POP label for sales promotion.

- It is difficult to set up a process for applying on the production line, and it is also difficult to secure personnel for applying.

02

Proposal from EDM

We propose to use the standard conveyor “LMUe6000JM”, which does not require design, to perform automatic applying.

03

Evaluation from customers

With the introduction of LMUe6000JM, the person in charge of hand pasting was able to take on another task, and efficient manufacturing was possible.

Even if the label is applied to the transparent container, there is little misalignment and the quality of the product has improved.

In the future, even if there is a request to apply a POP label at a spot, we can respond with confidence.