DT2000c [Dual continuous TTO]

Dual continuous TTO with "zero" downtime

without stopping the production line

DT2000c

- [Maximum printing speed]

416 mm/sec (25 m/min) - [Maximum printing area]

53 mm(W) × 150 mm(L)

- Print resolution 300dpi

- Radial ribbon save

- Auto calendar

- Barcode printing

- QR code printing

- “EUI2” by SD card

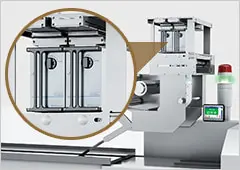

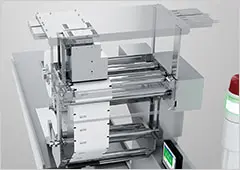

The continuous thermal transfer overprinter "DT2000c" is a dual TTO with two sets of printer sections in the same space as one conventional continuous TTO.

The “Non-Stop Mode” enables ribbon replacement and head maintenance without stopping the production line, and the “Twin Mode” realizes more flexible printing to meet the needs of production sites.

It is mainly suited for incorporation into continuous packaging machines such as horizontal pillow wrapping machines.

Two in one, dual thermal transfer overprinter

DT2000c's space-saving printer section achieves the performance of two printers by fitting two printer sections in the same amount of space as one conventional printer.

DT2000c also combines the input/output of each signal into a single system, allowing for processing that is identical to that of a conventional machine, and allows operation from a single operation terminal, just as if a single printer were being operated.

“Two modes” to meet the needs of production sites

Zero downtime when changing ribbons - Non-stop mode

In the non-stop mode, which enables switching of the printer section without stopping the line, the remaining ribbon level is automatically measured and the printer section is automatically switched when the ribbon ends.

The cassette of the printer section that is not printing can be removed and the ribbon replaced even while the printer is in operation, realizing “zero” downtime due to thermal ribbon replacement. This dramatically improves production efficiency.

Small pitch printing - Twin mode

In the twin mode, which enables printing equivalent to two printers in the space of one printer, two sets of printers can be operated alternately to support “small pitch printing,” which was difficult with a single conventional printer.

Newly designed modular cassette unit for increased production efficiency

The DT2000c features a newly designed modular cassette unit with the print head module mounted on the cassette side.

This has improved the ease of maintenance and replacement of the print head.

Improved printhead maintenance

The print head is located on the cassette side, making it easy to clean the head at hand.

In non-stop mode, cassettes can be removed for safe and reliable maintenance without stopping the production line while it is running.

Print head can be replaced with one-touch

A magnetic printhead detachment mechanism is used. One-touch replacement greatly improves the workability of printhead replacement.

This eliminates the risk of losing screws and other parts during operation and improves safety at the production site.

Equipped with new functions to improve and stabilize printing quality

Improved print quality and stability

Smooth drive is realized by the next-generation control / arithmetic device. In addition to our new technology, the improved line speed tracking of ribbon feed control contributes to overall improvement and stability of print quality.

Achieves stable initial printing even in low temperature environments

Equipped with a preheat function that realizes stable printing from the start even in cold regions or at the start of work in the winter morning. This makes it easier to maintain the condition of the print head and enables more stable operation.

Please note that the images provided are for the THP2000c model.

Radial ribbon save feature

The feature is using the entire width of the ribbon in radial direction printing. Auto layout of row to letter height.

Color touch panel controller “EUI2”

The color touch panel controller "EUI2" common to EDM is used for the operation interface. The easy-to-understand hierarchical system and large color LCD allow comfortable operation.

[feature]

- Easy operation, item switching, and parameter setting

- Large letters and icons on the top (operation) screen clearly display the machine's operating status

- Item search function by item name and key word

- Displays the preview in the actual print size

- SD card is used as the recording media

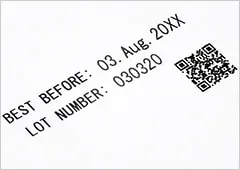

Printing sample

[Packaging form]

- Horizontal packaging

- Four-way seal packaging

[Printing data]

- Best-before date

- Expiry date

- Date of manufacture

- Production time

- Lot number

- Factory mark

Specification

| Model | DT2200c |

|---|---|

| Type | Dual Continuous Type |

| Print method | Thermal transfer |

| Printing resolution | 300dpi (12dots/mm) |

| Maximum printing speed | 416 mm/sec (25 m/min) |

| Maximum printing area | 53mm(W) × 150mm(L) |

| Font size | 24-96 dots (24 size/font) |

| Print extension | Date Format, Date Stamp with Offset, Time, Shot Count, Shift Code, Custom Code |

| Barcode | EAN8, EAN13, ITF, CODE39, CODE128, GS1-128, GS1 DataBar |

| 2-dimensional code | QR code, Micro QR code, DataMatrix |

| Data memory | SD card |

| Thermal printer ribbon | 400 m/roll (Max.) |

| Interface port | RS232C / RS422 / Ethernet (option) |

| Air supply | 0.2MPa-0.3MPa Clean dry air |

| Air consumption | 7ml/ cycle |

| Power supply | AC100V/200V, 50Hz/60Hz |

| Power consumption | 1kW |

| Body weight | Approx. 10kg |

| Dimensions | 233mm(W) × 193mm(H) × 235mm(D) |

| Configuration | Main body / Control box / EUI2 / Encoder |

| Usage Environment | Temperature : 5℃-40℃ Humidity : Under 90%RH (no dew condensation) |

| Option | Item editing software (GIE) |

※The above specifications may differ depending on the usage conditions, mounting conditions, use of mounting brackets, environment, etc. Specification and other information are subject to change without notice.

Main unit and related software correlation diagram